Fiberglass Air filter paper

Fiberglass Air filter paper

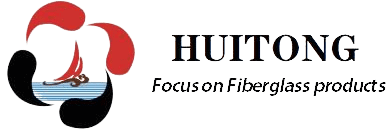

The ultra-fine fiberglass air filter paper is produced using a wet method. The product is composed of a combination of glass fibers and a resin system to provide specific filtration performance and physical characteristics.

The structure of the ultra-fine fiberglass air filter paper provides a high surface area “matrix” for capturing pollutants and other particles, while allowing high breathability.

The fiber size can vary to meet the filtration requirements of specific applications.

It has advantages such as stable chemical properties, strong heat stability, resistance to mold, toxicity, corrosion, and environmental friendliness.

The removal efficiency for particles with a diameter of 0.3 microns (1/200th the diameter of a human hair) or larger can reach over 99.97%, making it the most effective filtering medium for pollutants such as smoke, dust, and bacteria.

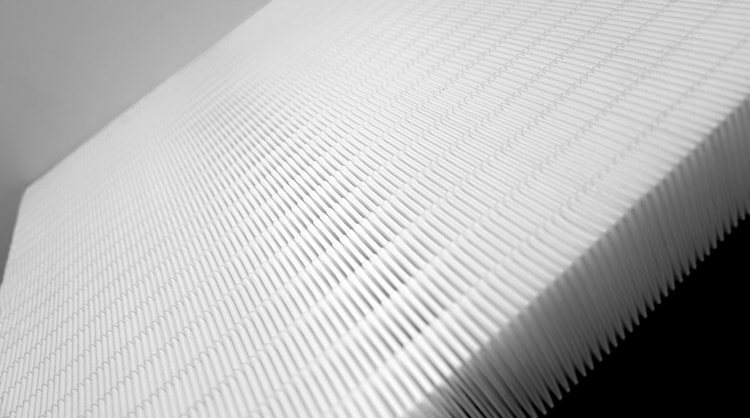

Application

- Cleanrooms are used in pharmaceutical production,

- microelectronics and precision instrument manufacturing,

- nuclear power, military industry, hospitals, airports, and other industries.

HEPA FITER

ULPA AIR FITER

AIR SHOWER

Industrial Clean Room

Biological Clean Room

Computer chip factory

Clean ROOM

Advantages

High Efficiency. The filter efficiency range is broad, covering ASHRAE HEPA and ULPA.

High Temperature Resistance.

The fiberglass filter paper has good performance in environments up to 300℃ due to its heat resistance.

Good weather resistance, long life.

It is also corrosion-resistant due to the inherent characteristics of glass fibers, making it resistant to acid and alkali as well as chemical corrosion.

High dust holding capacity.

Low air resistance.

High mechanical strength.

Parameter

HEPA (High-efficiency Particulate Air Filter)

(H10-H14)

For 100,000 to 10,000 grade clean room or workbench, nuclear power plant ventilation system, high-end household cleaners, air purifiers and gas masks, etc.

The fiberglass caliber is 0.5~2.0 micron and its high level of filtration efficiency for the smallest as well as the largest particulate contaminants can stop virus and germs ≥0.3μm with 99.995% efficiency.

Technical Data | Thickness (mm/100KPa) | Basis Weight (g/㎡) | MD Tensile Strength (KN/m) | CD Tensile Strength (KN/m) | MD Stiffness (Mg) | Efficiency(%)0.3μm | Resistance(Pa)5.3cm/s | Water Repellency(mmH2O) |

H10 (E10) | 0.33±0.02 | 72±3 | ≥ 1.2 | ≥ 0.5 | ≥ 1450 | ≥ 94 | ≤ 110 | ≥ 550 |

H11(E11) | 0.33±0.02 | 72±3 | ≥ 1.2 | ≥ 0.5 | ≥ 1450 | ≥ 98 | ≤ 160 | ≥ 550 |

H12(E12) | 0.33±0.02 | 72±3 | ≥ 1.2 | ≥ 0.5 | ≥ 1450 | ≥ 99.8 | ≤ 230 | ≥ 550 |

H13 | 0.33±0.02 | 76±2 | ≥ 1.2 | ≥ 0.55 | ≥ 1450 | ≥ 99.95 | ≤ 290 | ≥ 850 |

H14 | 0.33±0.02 | 76±2 | ≥ 1.2 | ≥ 0.55 | ≥ 1450 | ≥ 99.995 | ≤ 370 | ≥ 850 |

ULPA (Ultra Low Penetration Air Filter)

(U15)

Used for integrated circuit factory and grade 100, grade 10 and grade 1 clean room

Technical Data | Thickness (mm/100KPa) | Basis Weight (g/㎡) | MD Tensile Strength (KN/m) | CD Tensile Strength (KN/m) | MD Stiffness (Mg) | Efficiency(%)0.16μm | Resistance(Pa)5.3cm/s | Water Repellency(mmH2O) |

U15 | 0.35±0.02 | 76±2 | ≥ 1.2 | ≥ 0.55 | ≥ 1450 | ≥ 99.9995 | ≤ 420 | ≥ 850 |

Normal (F6-F9)

Used for integrated circuit factory and grade 100, grade 10 and grade 1 clean room

Technical Data | Thickness (mm/100KPa) | Basis Weight (g/㎡) | MD Tensile Strength (KN/m) | CD Tensile Strength (KN/m) | MD Stiffness (Mg) | Efficiency(%)0.3μm | Resistance(Pa)5.3cm/s | Water Repellency(mmH2O) |

F6(M6) | 0.33±0.02 | 72±3 | ≥ 1.2 | ≥ 0.4 | ≥ 1400 | ≥ 30 | ≤ 20 | ≥ 350 |

F7(M7) | 0.33±0.02 | 72±3 | ≥ 1.2 | ≥ 0.4 | ≥ 1400 | ≥ 40 | ≤ 30 | ≥ 350 |

F8(M8) | 0.33±0.02 | 72±3 | ≥ 1.2 | ≥ 0.5 | ≥ 1400 | ≥ 55 | ≤ 45 | ≥ 350 |

F9(M9) | 0.33±0.02 | 72±3 | ≥ 1.2 | ≥ 0.5 | ≥ 1400 | ≥ 80 | ≤ 75 | ≥ 550 |