PRODUCT

AGM Separator

AGM Separator & Pasting paper

for :

Lead-acid battery,

Automatic start-stop battery,

UPS battery power supply,

Telecommunication

Emergency Lighting Power Supply

Lead-acid battery,

Automatic start-stop battery,

UPS battery power supply,

Telecommunication

Emergency Lighting Power Supply

Pasting paper

"Roll and expand""line

"cast and panch"line

"cast and expand"line

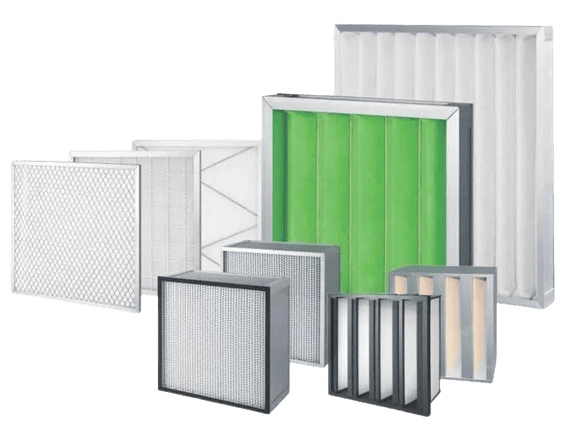

Air filter paper

HEPA Air Filter

ULPA Air Filter

FFU system

AIR Shower

Vacuum Insulation Panel Core Material(VIPs)

Wall Insulation

House Thermal Insulation Paper,

Insulation for RV (Recreational Vehicle),

insulation for yacht

refrigerated container,

refrigeration vending machine,

insulation for aircraft interior wall.

House Thermal Insulation Paper,

Insulation for RV (Recreational Vehicle),

insulation for yacht

refrigerated container,

refrigeration vending machine,

insulation for aircraft interior wall.

NEW PRODUCTS PROCESS

Step1:

Analyzing samples and product data sheets

After receiving customer samples or process sheets, the R&D department will conduct sample testing on the received samples and design a formula for the designated product.

Step2 :

The production planning department will then be responsible for small-scale production of the product.

Step3:

The quality department will conduct relevant experimental tests on the small batch of products. After meeting the requirements, the products will be sent to the customer for sample confirmation.

Step4:

After customer confirmed products quality,packing,seaport, the product will move into large-scale production. The process sheet and formula sheet will be compiled as controlled documents.

Professional Clients

0

+

Annual output

0

K

ton/year

Export Country

0

+